Description : Post-cooling module for adsorption C35 dryer - 621201

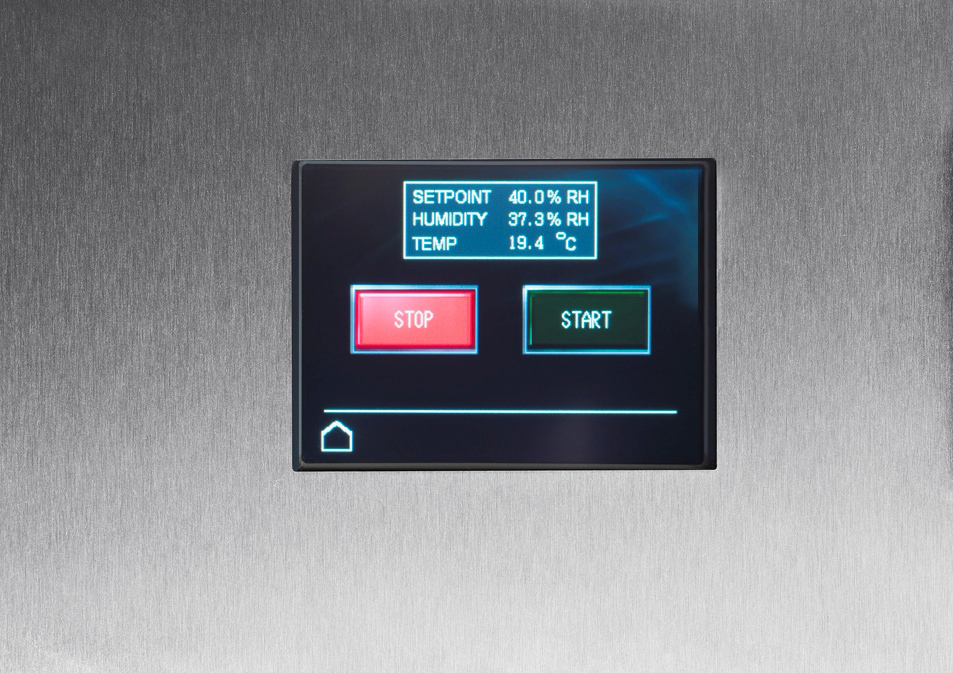

Post-cooling units being able to control the exact specifications of the air leaving the dehumidifier enables you to extract maximum benefit from Cotes humidity management.

If it is important to keep the process air at a consistently low temperature, a post cooling unit can be fitted after the adsorption rotor, as optional equipment.

Post-cooling units can be retrofitted to C35E/C35D dehumidifiers

with the PLC-C and PLC-D configuration.

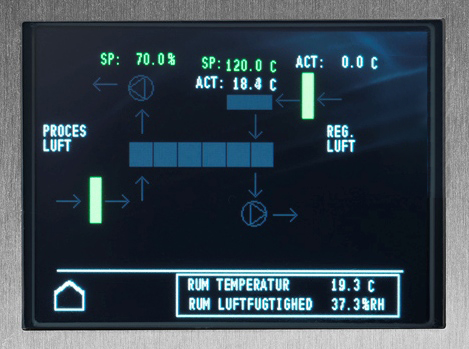

Schema : Post-cooling module for adsorption C35 dryer - 621201

Click the image to enlarge

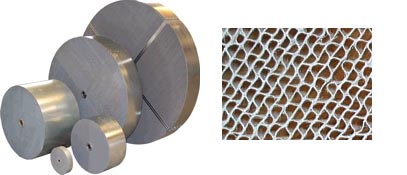

The air process (air to be treated) passes through the wheel in permanent rotation, which retains the moisture contained in the air. A flow of air heated by electrical resistors, called regeneration air, is injected into the wheel in the opposite direction. This hot air evaporates the water contained in the wheel and is then evacuated from the apparatus to the outside. Each of the two streams has its own fan.

The wheel is made from a minimum of 80% Silicagel, which is held by a solvent-free chemical solution based on fiberglass. In regeneration phase, the temperature of the wheel is about 120-140 ° C.

Youtube

Youtube  LinkedIn

LinkedIn