Description : Low pressure steam injection humidifier - SKD

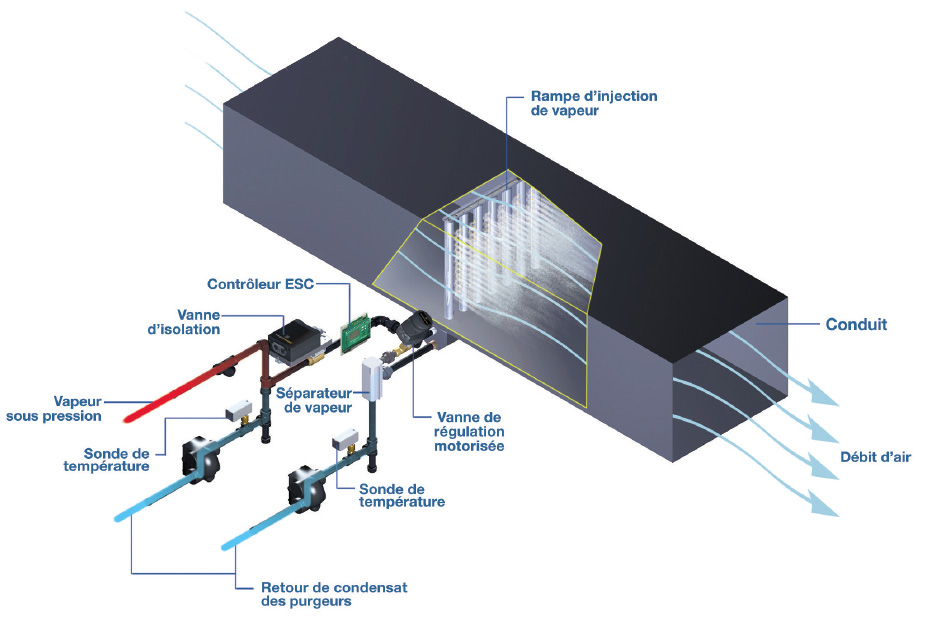

The SKD steam humidifier directly injects low pressure steam from a steam boiler directly into the air.

Benefits of the SKD:

- A customized design that fits your ability and distance without wetting required.

- 6 configurations of diffusers available: Multi-steam ™ SD, Multi-steam ™ HD, Multi-steam ™ HDR, or jacketed (single ramp, Multi-tube or mini Rack)

- ESC electronic controller unique in the industry. It controls the sequence of operation to optimize energy consumption and prevent the occurrence and spread of condensate.

Applications: :

The SKD Steam Humidifier is the ideal humidification solution when clean low pressure steam is available on site, such as:

- Hospitals and health facilities

- Printing

- Chemical Industry

- Tobacco

- Airports

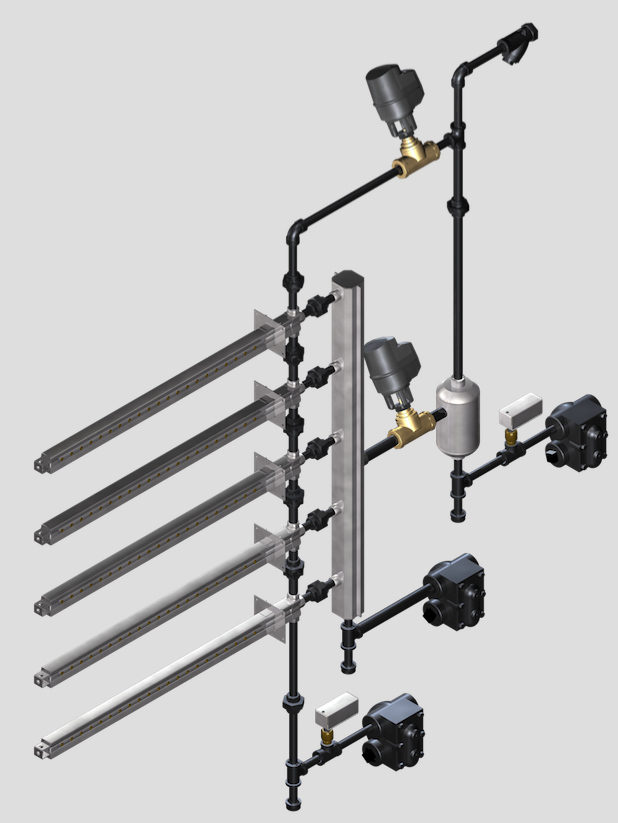

Typical installation: :

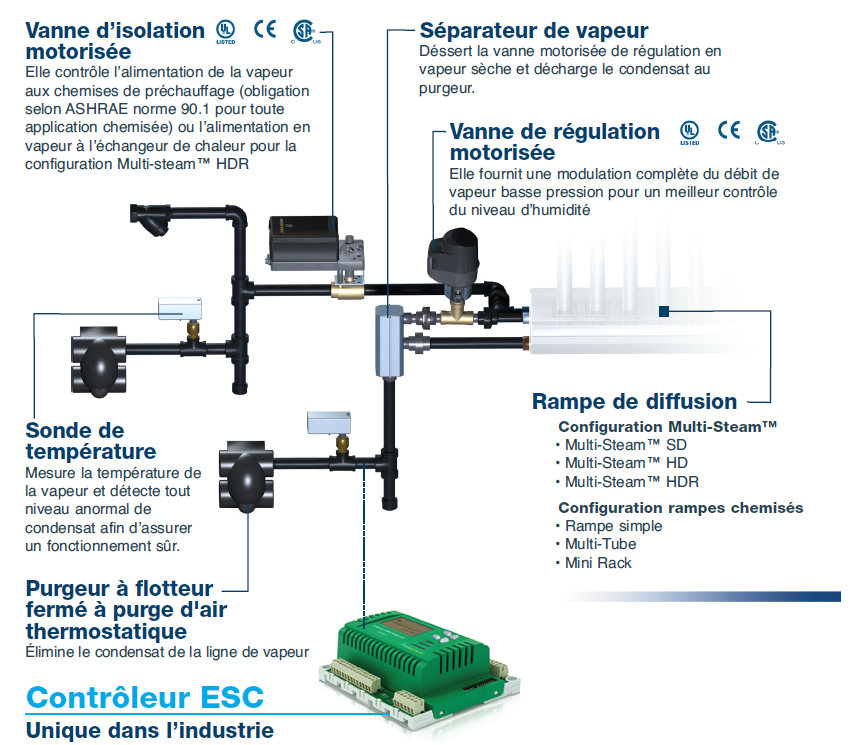

The SKD steam humidifier comes with all the components and accessories required to complete the installation. Depending on the selected configuration:

- Motorized insulation valve

- Motorized control valve

- Temperature sensors

- Steam separator

- Sieve

- Condensate trap (s)

- Electronic Controller ESC

ESC Controller, Unique in Industry: :

The ESC electronic controller is specially configured for each SKD steam humidifier application. It monitors the operating sequence in order to minimize energy consumption and prevent the appearance and spread of condensate.

- Controller with microprocessor, programmable on site

- Centralizes wiring to probes, valves and humidity signals

- Trouble-free startup and easy diagnosis

- 4 buttons and liquid crystal display wide and friendly

- Pre-configured in the factory according to the configuration and application

- Automatic linearisation of the valve regulation and steam flow to perfectly adjust the steam capacity

- Supply voltage of 24 VAC

- Compatible with BACnet or Modbus

Multi-Steam ™ Configurations

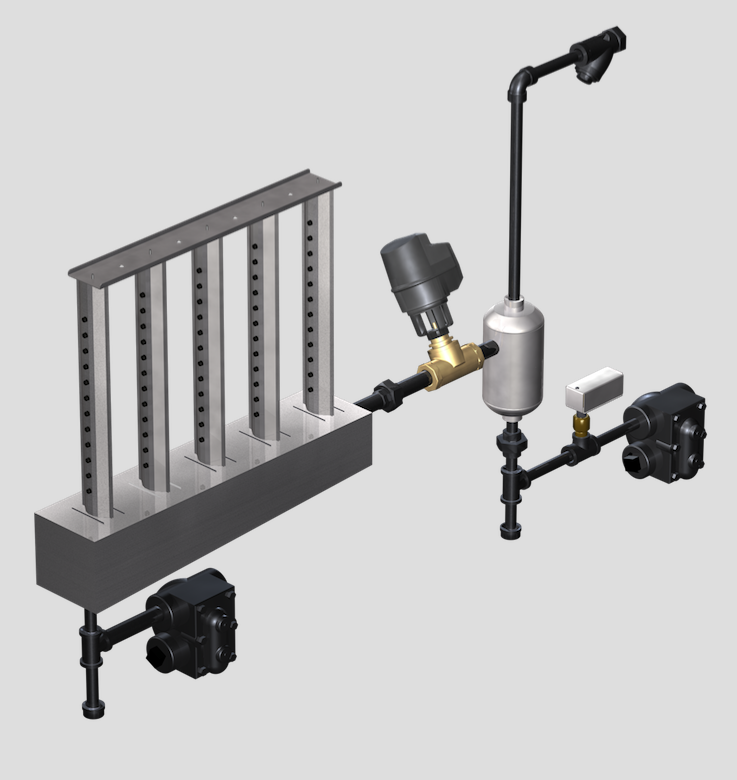

This configuration consists of a system of vertical diffusion ramps assembled on a common horizontal collector. When the moisture demand is reached, the electronic controller ESC slowly opens the motorized control valve which supplies the ramps from the common collector. The steam is diffused by the vertical ramps thanks to the multiple nozzles and mixes with the air to reach the desired degree of humidity.

Common Features: :

- Capacities from 2 to 525 kg/h. Greatest possible capacities

- Short absorption distance

- Preconfigured ESC electronic controller for the control of the opening sequence

- All components are stainless steel (no maintenance required)

Multi-Steam ™ SD

- Dissemination system at lowest investment cost

- The easiest to install: the favorite of entrepreneurs

- Collector with integrated slope: collection and evacuation of improved condensates

Multi-Steam ™ HD

- Same features as Multi-Steam ™ SD but with X-Stream ™ technology (see below)

Multi-Steam ™ HDR

- Equipped with X-Stream ™ technology (see below)

- Includes a re-evaporator for the re-vaporization of the condensates generated in the diffusion ramps thanks to the internal heat exchanger

- The most energy-efficient distribution system

- No drain operation, no loss of energy due to condensate evacuation

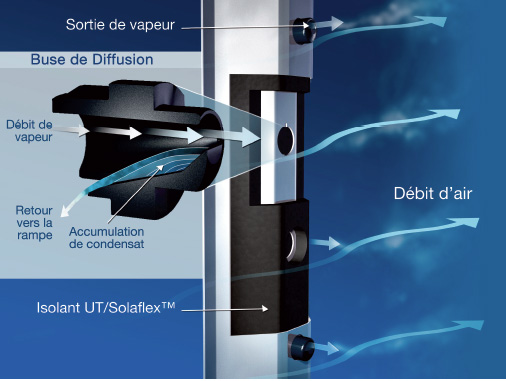

X-Stream ™ Technology

- Multi-Steam ™ HD and Multi-Steam ™ HDR Technology

- High-efficiency ramps and manifold insulation and patent pending diffusion nozzle design.

- Double wall stainless steel grade 304 with foam insulation Armacell UT / Solaflex ™

- Silicone diffusion nozzle designed to prevent the ejection of condensate

- Reduction of heat input to air by 85%

Configurations with lined ramps

This configuration consists of a single ramp or multiple jacketed horizontal manifolds connected to a common vertical manifold. In case of a moisture demand, the electronic controller ESC opens the motorized isolation valve in order to preheat the preheating jackets. This is to prevent any condensation in the inner tube which could be expelled into the duct or CTA during steam diffusion. When the preheating jackets have reached operating temperature, the electronic controller ESC slowly opens the regulated control valve which feeds the inner tubes from the common manifold. The steam is diffused by the horizontal ramps thanks to the multiple nozzles and mixes with the air to reach the desired degree of humidity.

Single ramp

- Ideal for duct installation

- Low capacity: from 2 to 80 kg/h

- Average absorption distance

- Preconfigured ESC electronic controller for the control of the opening sequence

Multi-Tube

- For duct or CTA installation

- Medium to large capacities: from 2 to 530 kg/h

- Short absorption distance

- Preconfigured ESC electronic controller for opening sequence control.

Mini Rack

Same features as Multi-Tube plus:

- Pre-assembled ramps on the collector

- Shortest distance without wetting

External Re-Evaporator

- Option available for Multi-Tube and Mini Rack configurations

- Increases efficiency and prevents condensate evacuation

- Re-evaporates the condensate generated in the collector

- No drain operation, no loss of energy due to condensate evacuation

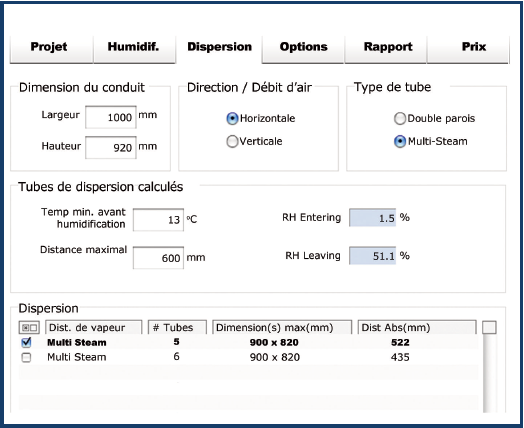

Humidisoft, select your SKD online:

Web application design and selection of humidification systems

Ready to select your SKD humidifier!

Neptronic has developed a web application that will save you time

Youtube

Youtube  LinkedIn

LinkedIn